Leak Detection

Leak is a problem that we often come across in vacuum works. A severe leak obviously stops the operation of a vacuum system, but even a small leak can cause quality problem. For example, in PVD coating process, during the heat up phase, when oxygen in the ambient air leak in to the chamber, work piece surface can be oxidized, subsequently causing poor adhesion or even coating non-stick.

Generally, a small leak is harder to tackle because of the difficulty to locate it. Technically, the severity of a leak is quantified by its ‘leak rate’, which is calculated according to the following equation:

(Ql—leak rate;△P—change of the vessel pressure; V—volume of the vessel;△T—the time period)it has the unit Pa.m³/sec or Torr.L/sec or mbar.L/sec.

(Ql—leak rate;△P—change of the vessel pressure; V—volume of the vessel;△T—the time period)it has the unit Pa.m³/sec or Torr.L/sec or mbar.L/sec.

The following example puts the size of leak rate in perspective. The inner tube of a bicycle tyre is roughly 4L in volume. When fully inflated, it can reach to 3 times of atmospheric pressure (i.e. 3 bar). With no more pumping up in the next 30 days, its pressure drops to 2 bar, therefore △P=1000mbar. Its leak rate;

Ql =1000mbar×4L/(30×24×3600) sec =1.5×10-3mbar.L/sec.

A leak rate of this scale can be easily detected by immersing the tyre in a trough of water. On the other hand, a refrigerator is supposed to work for 10 years without the need to refill refrigerant thus the permissible leak rate should be less than 7×10-6 mbar.L/sec. The leak rate of that scale can only be detected by a very high sensitivity method.

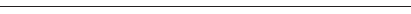

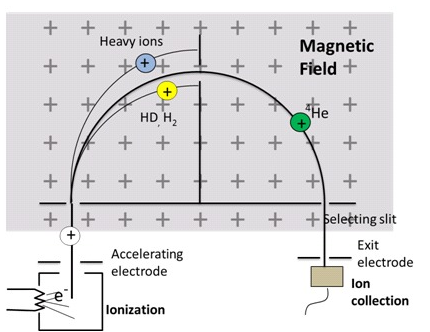

A He leak detector is the best leak detection device in the modern vacuum technology. Its sensitivity can be as high as 10-12mbar.L/sec. He gas is used as the tracer gas of this method with a detector that is similar to a mass spectrometer but specially designed only to detect 4He+ ions. Its working principle is shown in Fig. 1. This method is so sensitive that even small trace of He in the residual gas can be detected.

Fig. 1 Schematic drawing to show the working principle of a He leak detection cell.

Fig. 1 Schematic drawing to show the working principle of a He leak detection cell.

When doing leak detection to a large size vacuum chamber, it is necessary to get a sufficiently high vacuum in order to get the highest sensitivity of the He leak detector, thus the pumping system of the tested vacuum unit should also be running to achieve reasonable good vacuum. The leak detector should be connected to the high speed pump port or to its close proximity. Also He is lighter than air, leak test should be conducted on the high points of the system first, and do not spray excessive amount of He gas to increase its concentration in the ambient to avoid false detection.

Our technical staffs in Techmart are experienced in vacuum techniques. We have purchased the most advanced leak detector for routine system maintenance work to our coating systems to ensure that they are being kept in the best operating conditions. Our well trained technicians can provide leak detection for your devices and systems, please contact us for enquiry.

Generally, a small leak is harder to tackle because of the difficulty to locate it. Technically, the severity of a leak is quantified by its ‘leak rate’, which is calculated according to the following equation:

The following example puts the size of leak rate in perspective. The inner tube of a bicycle tyre is roughly 4L in volume. When fully inflated, it can reach to 3 times of atmospheric pressure (i.e. 3 bar). With no more pumping up in the next 30 days, its pressure drops to 2 bar, therefore △P=1000mbar. Its leak rate;

Ql =1000mbar×4L/(30×24×3600) sec =1.5×10-3mbar.L/sec.

A leak rate of this scale can be easily detected by immersing the tyre in a trough of water. On the other hand, a refrigerator is supposed to work for 10 years without the need to refill refrigerant thus the permissible leak rate should be less than 7×10-6 mbar.L/sec. The leak rate of that scale can only be detected by a very high sensitivity method.

A He leak detector is the best leak detection device in the modern vacuum technology. Its sensitivity can be as high as 10-12mbar.L/sec. He gas is used as the tracer gas of this method with a detector that is similar to a mass spectrometer but specially designed only to detect 4He+ ions. Its working principle is shown in Fig. 1. This method is so sensitive that even small trace of He in the residual gas can be detected.

When doing leak detection to a large size vacuum chamber, it is necessary to get a sufficiently high vacuum in order to get the highest sensitivity of the He leak detector, thus the pumping system of the tested vacuum unit should also be running to achieve reasonable good vacuum. The leak detector should be connected to the high speed pump port or to its close proximity. Also He is lighter than air, leak test should be conducted on the high points of the system first, and do not spray excessive amount of He gas to increase its concentration in the ambient to avoid false detection.

Our technical staffs in Techmart are experienced in vacuum techniques. We have purchased the most advanced leak detector for routine system maintenance work to our coating systems to ensure that they are being kept in the best operating conditions. Our well trained technicians can provide leak detection for your devices and systems, please contact us for enquiry.