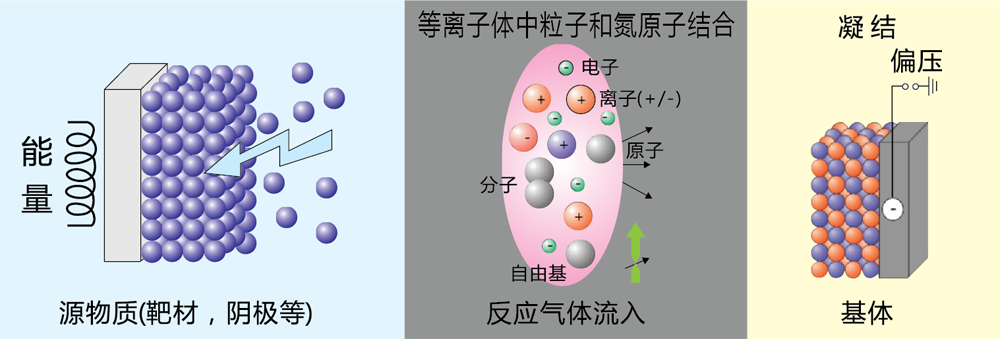

PVD Coating Technology PVD(Physical Vapor Deposition) describes as ionizing of gas and vaporized material formed from metallic plate material and sticking onto various workpiece which forms a 1-10um super hard film by adopting electric arc discharge technology with low voltage and high current performed under vacuum conditions. It is a vacuum-sealing filming with no contamination. This PVD solution can easily acquire ceramic coating and composite coating with super hardness and wear-resistance while others hardly can achieve. PVD coating used in cutting tools, molds can lengthen life exponentially which leads to the realization of high-yields but low-cost. Moreover, PVD coating technology supports a relatively low temperature which ensures coating onto most workpiece.

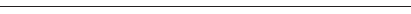

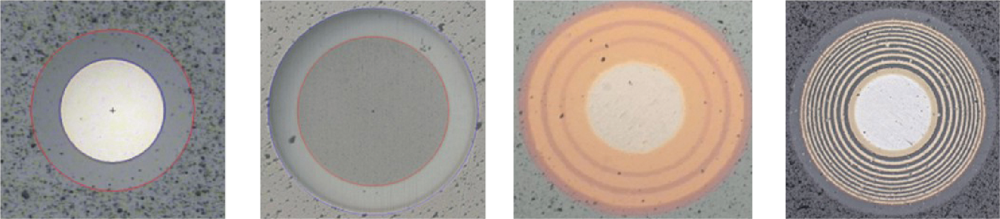

Comparison of micro-structure

|

||||||||||||||||

Coating structure

|

||||||||||||||||